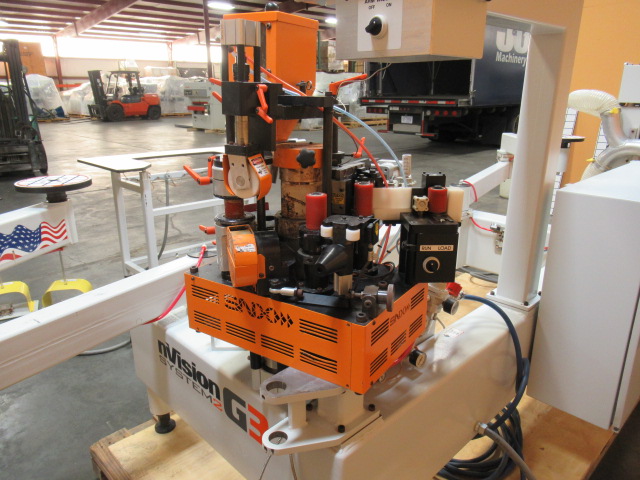

SNX SYSTEM 2 G3 CONTOUR EDGEBANDER

- stock number

12688 - new/used

Used - year

2019 - fob

Sanford, NC - electrical

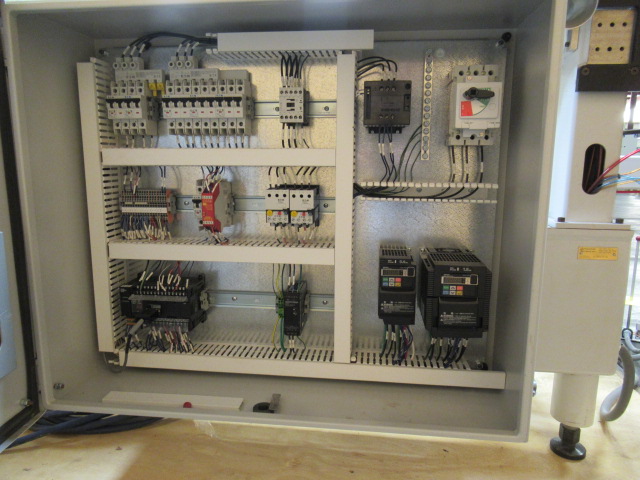

230V, 3 Ph, 60 Cy - condition

CLEANED/CHECKED

Share:

Replacement

~$85,000

CostOUR PRICE

$49,500

Have questions?

Prefer to discuss

by phone or email?

We're here to help!

P: 919-776-8341

sales@jgmachinery.com

Description

Main Machine Features:

- Non-stop operation utilizing twin vacuum arms and 3 workstations

- Large touch screen controller

- Large heavy duty movable vacuum pod arms for ease of operation (max panel weight 230 lbs.)

- Triax 3-Axis laser system to insure consistently tight butt joints on panels

- Designed to apply hot melt EVA adhesive and edgebanding from .5 to 3 mm

- Trimming unit to facilitate trimming of the top and bottom overhang of the edgebanding

- Armordrive Kevlar lower belt drive system for smooth, quiet, long life operation - no lubrication

Digital Control Features:

- Digital control: Ability to program length/electronic encoder, cut off point for guillotine

- Ability to select laser measurement to assist encoder for more accurate splicing of joints

- Temperature on/off (separate temperature thermostat to adjust adhesive temperatures

- Screen with graphic interface makes programming easy

- Ability to select manual or semi-automatic function

- Variable speed manual adjustment

Twin Workpiece Holding Mechanism Features:

- Utilizes a pneumatic vacuum pump system

- Vacuum is provided via a rotating vacuum pod table

- Additional vacuum tables are available but not included (part specific)

- Work piece feeder is driven with an extra wide rubber roller and double upper support rollers

- Vacuum table are at the end of a large heavy duty articulating arm

Edge Coil Magazine Features:

- (1) universal magazine rotating table for coiled material

- automatic guillotine for coiled material up to 3 mm x 45 mm

- Guillotine is activated by a digital/laser encoder reader or by manual foot operation

- Self engaging Triax 3-axis laser system allows accurated reading of the contour of the panel and of panels with slight warping or sagging

Gluing Station Features:

- Glue pot with 1 Kg. capacity

- 10 to 60 mm work piece capacity (note: work piece thickness is dependent upon edge tape thickness)

- Glue tank made from aluminum for easy heat dissipation and cleaning

- Digital glue temperature settings

- Dual rollers to copy the shape/contour of the parts being banded

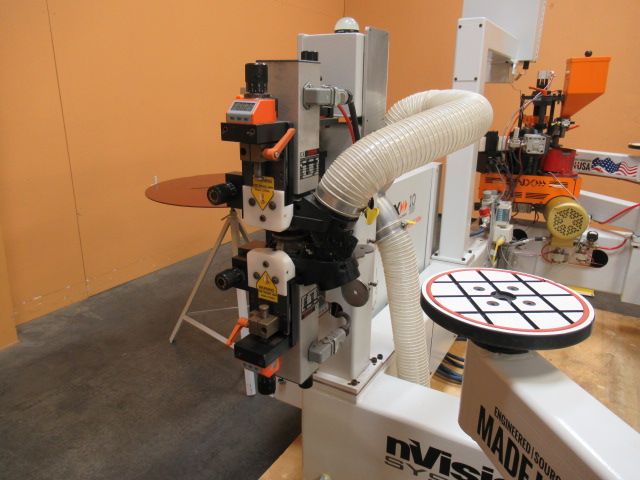

Top and Bottoom Trim Station Features:

- (2) .75 hp 12,000 rpm high frequency motors for edge trimming

- Vertical and horizontal tracing via roller transer rollers and pad

- Maximum edge strip thickness 3 mm (up to 45 mm panel thickness)

- Maximum edge strip height: 60 mm

- Radius capability up to 3 mm radius

- Manual adjustment of the trim motors for workpiece thickness via hand lever

- Pneumatic opening of the trim motors fo facilitate the introduction of the panel

- Guiding and positioning of the trimming function around the contour of the panel is done manually by the operator

- Pneumatic exclusion of the trim unit via auto switch

- (2) cutterheads with stepped radius cutters of 1,2, and 3 mm

- "Rapidset Copy Shoe Turret" easily switch from 1,2, or 3 mm banding

Working Dimensions:

Edge coil thickness: .5 to 3 mm (.5 mm thin tape ONLY with proper low temp adhesive)

- Work piece min: 150 mm diameter

- Work piece max: 2400 x 2400 mm

- Work piece thickness: 1- to 60 mm

- Edgeband thickness: .5 mm to 1 mm for panels up to 60 mm thick

2 mm for panels up to 60 mm thick

3 mm for panels up to 45 mm thick

- Minimum outside radius: 30 mm(note: based on 1 mm thickness of banding

- Minimum inside radius: 150 mm

- Feed speed (rotation): 16 fpm

- Air requirements: 6 bar (90 psi)

- Electrical requirements: 10 amps@ 230 Volt 3 phase

- Footprint required: 19' x 10'8"

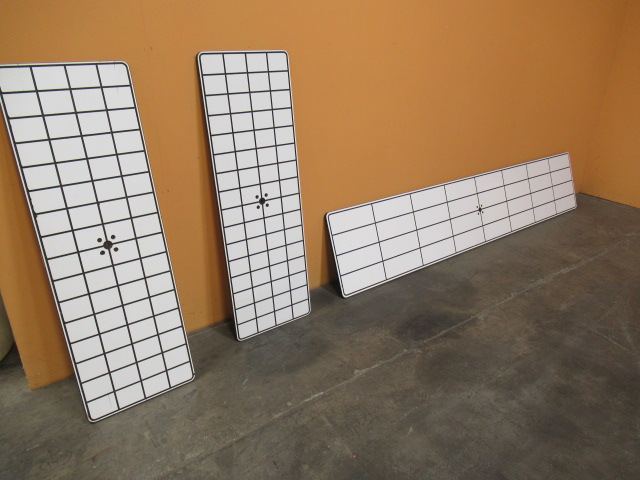

- Note: includes (2) optional 48" x 16" vacuum tables and (1) 96" x 18" vacuum table

Prices and specifications are subject to change without notice. Dimensions and weights do not include crates or packaging. We measure and weigh each machine and/or crate prior to shipping and will be happy to provide this information to you upon request.

Connect with us