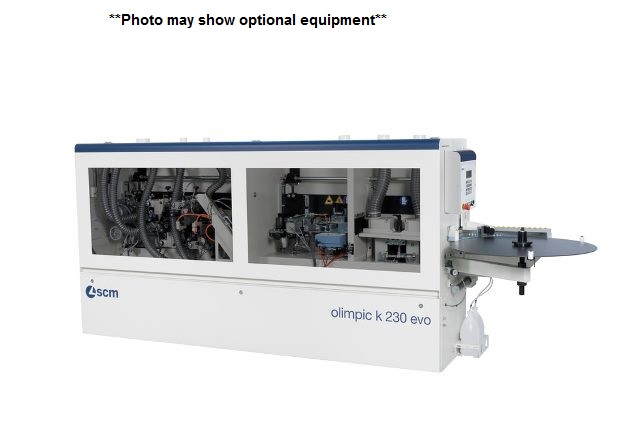

SCM OLIMPIC K 230B EVO EDGEBANDER

Stock Number:

K230BEVO

Condition:

NEW

Electrical:

230V, 1 Ph, 60 Cy

FOB:

SOUTHEAST

MSRP:

~$0

Our Price:

$0

Freight Charges Not Included

Automatic single sided edgebander designed to be used for edgebanding straight vertical profiles with coiled material (veneer and PVC) and with strips (high-pressure laminate and solid wood) with a maximum thickness of 3mm.

MACHINE BASE:

The machine base is made of a tubular steel structure and is designed to assure maximum stability and accuracy.

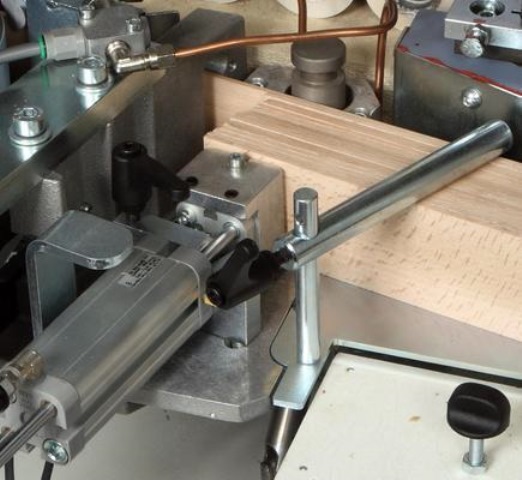

PRESSURE BEAM:

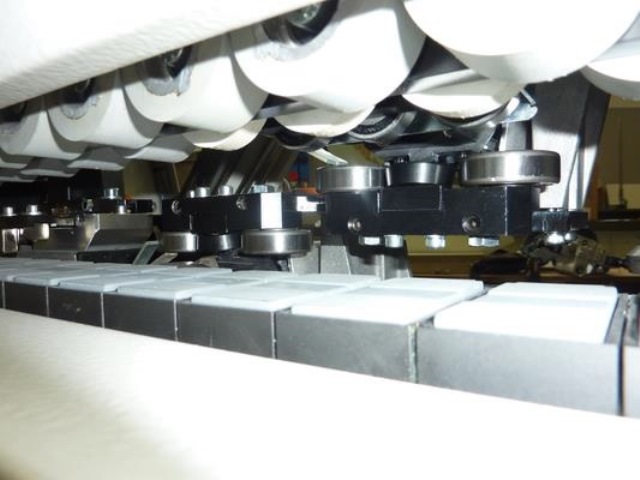

All operating units raise and lower simultaneously when the pressure beam is adjusted. No adjustment is required for the glue roller when changing panel thickness. The pressure beam has digital height indicators and a double row of pressure rollers with steel bearings.

PRIMARY SPECIFICATIONS:

- .4 mm to 3 mm edgebanding thickness capacity

- 3 mm guillotine capacity

- 3/8" min. to 1-15/16" panel thickness

- Minimum panel length is 5-1/2"

- Minimum panel width is 2-3/8"

- Minimum distance between panels is 22"

- Combination cutter for radius, solid and thin tape

- Feed speed 30 FPM

MAJOR FEATURES:

- The K230B is equipped with an Orion 1 Plus controller, fixed, located at the infeed of the machine. It is capable of operating all the work units via soft touch buttons, it pneumatically tiltís the end trim unit from the control panel, it eliminates the use of micro switches, as well as control the temperature of the glue. It is tilted slightly upward for a more ergonomically friendly position for the operator.

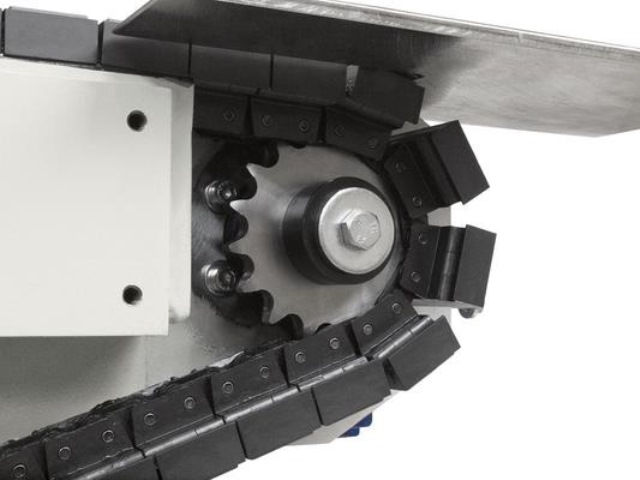

- Feed chain with replaceable track pads

- SGP-E Glue Pot - Quick heat up time due to the small glue pot. Reverse rotation of the glue roller for the application of solid wood. Double Thermo Regulation for easy use of both EVA and PUR glue. Color change and glue pot cleaning are able to be completed in minutes, as opposed to hours.

- 2-roller pressure section with automatic strip magazine

- (2) .25 HP motors for end trim unit on THK guides with pneumatic tilt

- (2) .50 HP top and bottom trim motors with 15 degree conical cutter and straight insert cutter

- Adjustments via mechanical digital readouts

- Pneumatic positioning through the controller

- "RC-M" Glue scraping station

- Buffing unit with (2) .25 HP motors that can be tilted up to 12 degrees

- Mechanical digital readout

- Adjustable side support

- Acoustical safety enclosure

- Air Requirements: 90 psi

- Dust Extraction: (2) 2" and (1) 3" port