LEADERMAC 623C MOULDER

- stock number

623C - new/used

New - year

- fob

PACIFIC NORTHWEST - electrical

460V, 3 Ph, 60 Cy - condition

NEW

Share:

OUR PRICE

Inquire

Have questions?

Prefer to discuss

by phone or email?

We're here to help!

P: 919-776-8341

sales@jgmachinery.com

Description

Leadermac (LMC) manufactures to the highest quality standards. They offer all of the latest moulder technology available today with simple entry level manual setwork systems, all the way up to fully CNC programmed solutions. With LMC we can offer machine solutions that will meet or exceed your requirements, at a price level that is extremely competitive. LMC has the resources and experience to design and manufacture moulders for all standard and many special applications, to ensure you receive the machine that is designed for your needs at a price that makes sense.

SPECIFICATIONS:

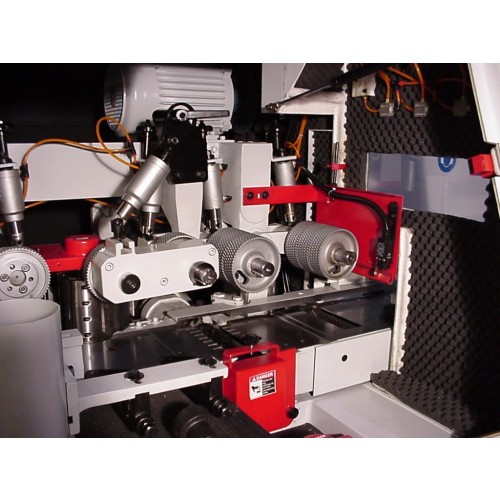

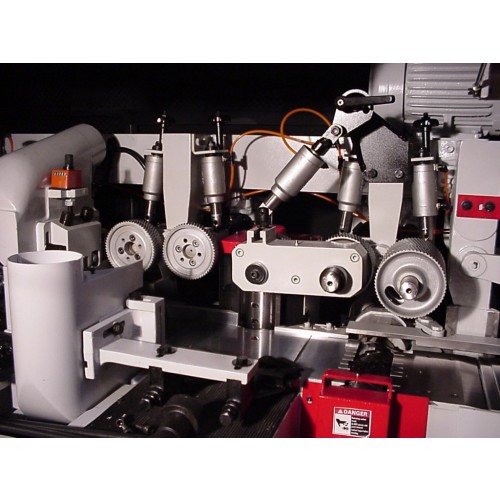

- 6-Head moulder

- 9" Wide capacity

- Minimum length of material - 8" (butt fed)

- Axial adjustment side heads - 1.6" (40 mm)

- Axial adjustment top/bottom heads - 0.8" (20 mm)

- Variable Feed speeds of 20 to 100 FPM

CONFIGURATION:

- 1st head: 10 HP bottom

- 2nd head: 10 HP right side

- 3rd head: 10 HP left side

- 4th head: 15 HP top

- 5th head: 20 HP top

- 6th head: 15 HP bottom

- All spindles are 1-13/16" diameter and standard 6000 RPM

FEATURES:

- All spindles have horizontal and vertical adjustment from the front of the machine

- Serrated steel feed rollers before top horizontal head

- Rubber coated feed rollers after top horizontal head

- (3) Full width driven bottom infeed roller

- Powered raise and lower of feed support beam

- All top rolls are pneumatically tensioned

- Edge reference straightening system

- All tables, bedplates, chipbreakers, pressure plates, and fences are hardened chrome for better wear resistance

- Auto-lubrication to the feed table with timer control

- Centralized grease lubrication system to all main slides & grease points from front locations

- Limit switch at infeed to prevent feeding of oversized material

- Dust collection requirements: 4,095 CFM (based on 5,000 fpm velocity)

- Air pressure requirements: 85 PSI

- Machine weight: 11,650 Lbs.

INCLUDES: Installation and (1) Complete set of cutterheads for 9" Max width included: Carbide spiral 1st bottom head and (5) standard 4-knife heads.

OPTIONS:

- Electronic DC Brakes (US manufactured) for the Cutterhead Spindle Assemblies including small steel enclosure that can be mounted separately or can be mounted on top of the main electrical enclosure.

Benefits - Quick Stopping of the Cutterheads for Safety & for Faster Cutterhead & Pattern Change.

Price: 460 Volt - 6 Brakes $ 1,330.00 ea x 6 = $7,980.00

- LMC MOU200600X29 Cutterhead Setting Stand for measuring radial diameter before and after grinding, to determine change in radial diameter. The dimensions obtained can be used to set the dual mechanical digital readout on the moulder. Price: $1,395.00

Comments:

Request a comprehensive quote today!

Prices and specifications are subject to change without notice. Dimensions and weights do not include crates or packaging. We measure and weigh each machine and/or crate prior to shipping and will be happy to provide this information to you upon request.

Connect with us